KB-10 to KB-50 booster compressors are well suited to applications needing modest air volumes at pressures upto 580 psig. Mounted on heavy-gauge base plates with anti-vibration pads, Kulmec boosters eliminate the need for reinforced foundations and floor fastenings For larger volumes of air, Kulmec Extra Pressure models offer a combination of higher flows and increased discharge pressures to 650 psig.* Mounted on heavy gauge steel bases with vibration isolators, these units offer smooth, quiet operation and eliminate the need for reinforced foundations and floor fastenings.All Kulmec boosters feature precision manufactured pumps with high quality cylinders.

KE 30-50 are innovative, oil injected Electrical Portable screw compressor. This single axle compressor is powered by a three phase TEFC squirrel cage motor with class F insulation and are suitable for varied application in Mining & construction industries. These compressors can be used for operating different tools like Rock Drills, Demolition Tools, Chipping Hammers, Rammpers/Tampers. Impact Wrenches, Grinding Tools & for Sand Blasting too.

Features

- Standard Starter Panel – Kulmec offers an enhanced starter control panel to monitor and regulate booster operation. The starter is designed to be wall-mounted in skid mounted and in-built in portable trolley mounted.

- High Quality Components – With of experience of years machining quality components, Kulmec designs and builds its high quality pistons, cylinders, valves, and other components to exacting specifications. Completed boosters are factory-tested to our rigorous quality standards.

- Advanced Cylinder Technology – Kulmec industrial booster cylinders are bored with super precision and finished by a special process that ensures minimum oil consumption and negligible wear for great durability.

- Effective Cooling – The rugged after-cooler in our two cylinder machines is efficient and maintenance

free, achieving low compressed air outlet temperatures. - Manual Belt Tensioning -A simple slide based v-belt tensioner makes it easy to adjust belt tension and avoid misalignment.

- Electric Motor– Our premium, TEFC motors have class F insulation and are EISA compliant, 3-phase.

- Low Vibration – Our boosters are built on durable steel base frames with anti-vibration mounts for quiet, smooth operation.

- Durable High Pressure Pumps– Our high pressure pumps feature lower rotational speeds to promote extended operational life and consistent efficiency.

- Low Discharge Temperatures- A generously proportioned after- cooler keeps the compressed air outlet temperatures comfortably low on air-cooled models.

- Water-Cooled After-Cooler- A water-cooled after- cooler is offered on the KB-50 to achieve discharge approach temperatures as low as 11°F.

- Forced lubrication- A forced lubrication system provides increased reliability and service life of the pump. Full-flow filtration extends the oil change interval.

- Instrument Panel- Our standard instrument panel contains gauges for air temperature, oil pressure, inlet air pressure, and discharge air pressure.

ADVANCE Features

These units include a high pressure discharge hose with check valve for flexible connection to the system. Inlet filters with automatic drain traps remove contaminants to protect the booster and improve compressed air quality. All components are arranged for both safety and easy service.

Premium efficiency TEFC motors provide energy savings and extend equipment life. Aluminum cylinder heads and finned copper cooling pipes promote efficient after-cooling for longer duty cycles.

Premium efficiency TEFC motors offer energy savings and long equipment service life. The automatic belt drive tensioning system ensures consistent efficient power transmission and prolonged belt life. Other features, such as controls and coolers, have been enhanced to meet the demands of larger applications

Application

- Blast hole drilling

- Line drill

- Water well boring

- Crawler drill

- Demolition Tools

- LD4 drilling

- Chipping Hammers

- Jack hammer / Rock drill

- Surface preparation (sand / shot / dry ice blasting)

- Shot creting

Technical Specifications (reciprocating air compressor)

| Max Working Pressure | 230 psi | 16 bar |

|---|---|---|

| FAD @ Max working Pressure (90 psi inlet) | 740 cfm | 20.9 m3/min |

main Specifications

| Booster Specification | Single stage, 4 cylinder |

|---|---|

| Air Intake Air intake Filtration Air intake Actuator | 3″ (76 mm) Inlet Dual Filtration, With water separation Pneumatic operated |

| Air Discharge Piate-Seal After Cooler | With steel hose plate-seal after cooler Requires min, 2 gpm (7.6 Ipm) of water |

| Discharge Valve | 2″ (55mm) |

| Safety Release Valve | Set at 300 psi |

| Pressure Gauge | Input Pressure Out Put Pressure Pressure Gauges Compressor Oil Pressure |

| Electrical System | Star Delta Starter |

| Safety Shutdowns | Low Mine Air Pressure Safety Shutdowns Low Water Pressure Low Compressor Oil Pressure High Discharge Air Temperature |

| Power Pack | 75 HP (55KW) TEFC |

Air booster option

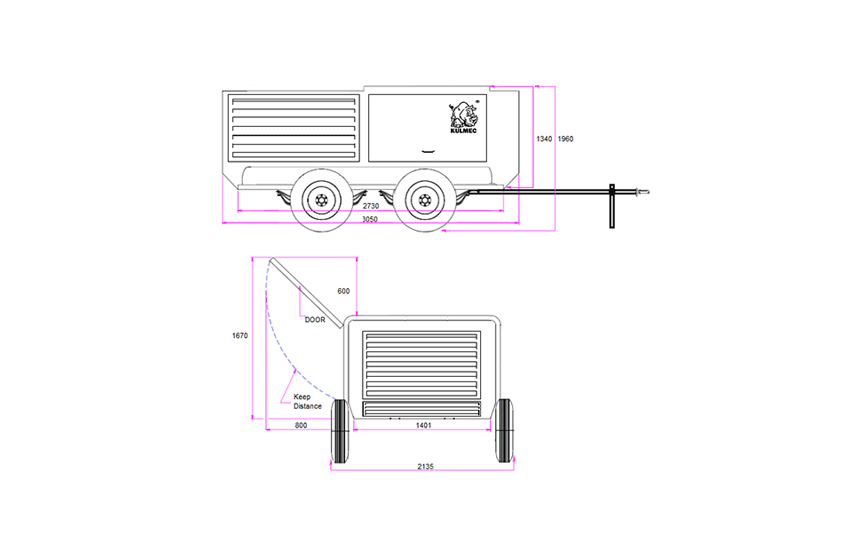

| Towing Package | Single Axle Air Filled Tires Towing Package Towing Tongue with replaceable eye |

|---|---|

| Fire Extinguisher | Powder Type Fire Extinguisher 4 Kg. Capacity, filled with MAP Powder |

| Break | Fittings with hand break |

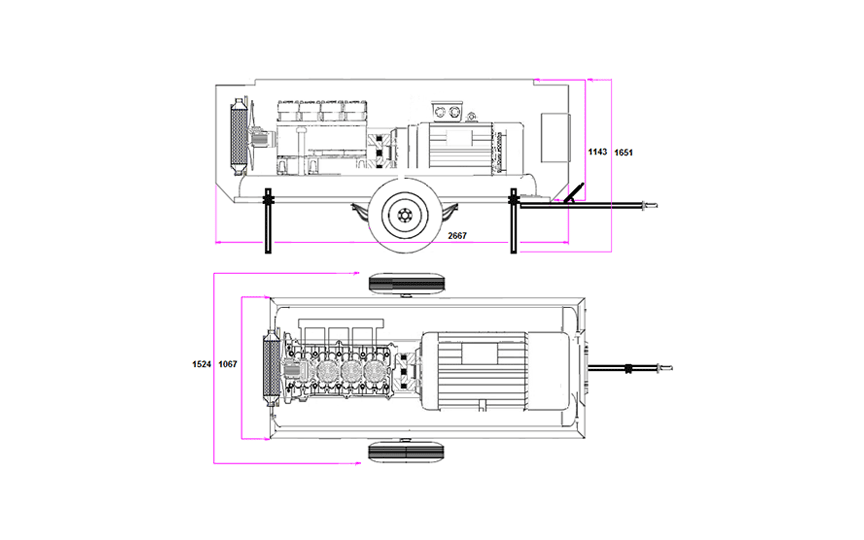

dimensions

| units | Length | Width | Height |

|---|---|---|---|

| mm | 2667 | 1524 | 1651 |